3D printing technology has been around for several years now, and it’s evolved considerably over that span of time. Like a handful of other modern innovations, however (virtual reality certainly comes to mind), it has faded somewhat from the headlines. So, in the early days of 2020, we thought we’d check in on some of the developments and realities defining the state of 3D printing at this point.

Consumer Printers Remain Expensive

One might expect that by this point there would be some high-end 3D printers that were more or less affordable for the average consumer – or at least not significantly more expensive than other tech products. However, as of now, consumer printers remain quite expensive.

Popular, known printing brands like HP – which, incidentally, we highlighted over the release of a new high-capacity printer just last July – are focusing primarily on commercial application. And those companies that are selling 3D printers to the public are mostly doing so for $1,000 or more. You can find a few small-scale options roughly in the $500 to $800 range, but for the most part, this is still a very pricey market (not to mention there are ongoing material costs to consider).

Industry Use Is Accelerating

If the average consumer has a hard time getting in on personal 3D printing, the counterpoint is that industry-level use of this technology is accelerating. On this level, too, 3D printing used to be quite expensive, and there were limited options for companies seeking manufacturing help.

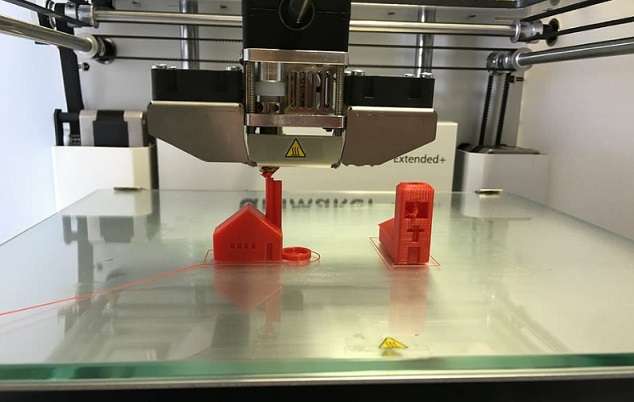

Now though, 3D printing services can meet companies’ needs in a more satisfactory manner, which is helping to accelerate usage. According to Fictiv, high-resolution functional prototypes and custom parts for product lines alike can be printed in just days, and at reasonable costs relative to the project at hand.

That degree of swift turnaround makes 3D printing all the more appealing. Companies can quickly test 3D-printed prototypes and rethink their designs if necessary. And if the prototypes work out, they can immediately explore the beginnings of product lines that will in many cases generate the bulk of their business.

More Materials Are Being Used

This is a very important development that doesn’t get much coverage, except among those who are actively dedicated to 3D printing. Simply put though, printing machines are being improved to handle a significantly broader range of materials than they could work within the early going. At this point, there are dozens of possibilities, with metals being among the newer and more significant additions. But as you might imagine, the more materials there are on the table, the more 3D printing can do across all applications and industries.

Ambition Has Only Grown Greater

As all of the above developments have unfolded, it’s important to note that ambitions for 3D printing have only grown greater. With better machines, improving efficiency, and additional materials, innovative thinkers are plotting out all sorts of interesting ways for 3D printing to impact the world. Many companies are already in the process of printing out complex medical devices in an affordable manner.

Some are producing ideas for how to use various 3D-printed materials to repair damaged aspects of the environment. And perhaps most exciting of all is the potential for 3D printing to change how we plan construction in cities; Smart Cities Drive suggested this process could simultaneously changes cityscapes and boost sustainability, not to mention provide durable, affordable housing. Altogether it’s becoming clear that 3D printing is going to accomplish wonders for our world.

This makes for a pretty exciting outlook as we begin the new decade. One can only imagine what we’ll be talking about where 3D printing is concerned another five years from now.